AI implementation

AI in Supply Chain and Logistics [20+ Practical Applications]

18 min read

—

Jul 6, 2022

Artificial intelligence is changing the supply chain and logistics industry. Learn about different applications of AI in supply chain and logistics.

Guest Author

According to a McKinsey report, artificial intelligence (AI) will create an entirely new logistics paradigm by 2030.

Why?

Well, technology continuously outperforms humans at repetitive but “mission-critical tasks.”

What’s more, a study from Meticulous Research estimates that by 2027 AI in supply chain management will have reached almost 22B US dollars.

What does this all mean?

We’re on the brink of a new era of automation. And in this article, we’ll show you some of the most revolutionary applications of AI in supply chain and logistics.

Here’s what we’ll cover:

Driverless delivery trucks

Product localization and identification

Warehouse automation and management

Shipment load monitoring

Defect inspection and quality control

Docks and parking lot occupancy detection

Intrusion and theft detection

BOL documents processing

Driverless Delivery Trucks

This first example that illustrates the application of AI in the supply chain comes from trucking.

Trucking in the US is the clear leader when it comes to freight movement and supply chain management. According to McKinsey, 65% of the US’s consumable goods rely on trucks to get them to market.

However, it comes at a huge cost, with constantly increasing freight rates anticipated to raise global import levels by as much as 11%. Consumer prices, meanwhile, could increase by 1.5% over the next 12 months.

Other challenges to the freight industry’s logistics operations include a shortage of truck drivers. And when the shortage amounts to over 80,000, “hiring more drivers” doesn’t come across as a viable solution.

Enter AI.

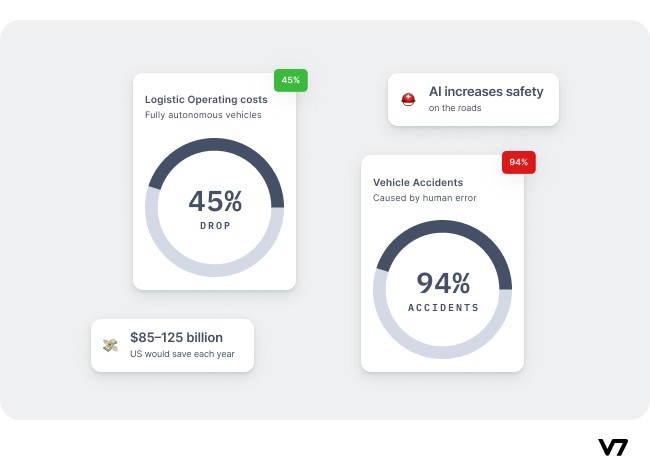

It’s estimated that with fully autonomous vehicles, operating costs could drop by around 45%. This would save the US for-hire trucking industry between $85–125 billion each year.

In fact, autonomous vehicles could also contribute to increasing safety on the roads, with human error being the cause of 94% of serious vehicle accidents.

How to implement artificial intelligence in trucking?

Thanks to cameras and sensors, AI models can understand what’s happening on the road and use predictive analytics to compute what will happen next.

The most vital part of this happens when the model is trained.

Thanks to such advanced processes as semantic segmentation, detailed 3D mapping, and, object detection, AI can detect roadside objects including pedestrians, lane markings, traffic lights, and road signs.

And once the system has been programmed so that the truck performs the right actions at the right time—like braking or speeding up—the driverless truck is ready to hit the road.

Pro tip: Whether you use driverless trucks or not, consider utilizing predictive analytics maintenance to predict exactly when a vehicle might require servicing. This allows you to schedule a service in advance, avoid unnecessary downtime, monitor fuel usage, and boost operational efficiency.

Plus, some other applications of AI in logistics can help you with route optimization and fleet management. For example, you can plan your routes with greater accuracy, taking into account weather and traffic conditions.

Products Localisation and Identification

There are many uses for AI in supply chain, with some of them able to improve your warehouse operations.

For example, you can start with optimizing your product localization and identification.

But what is this in the first place?

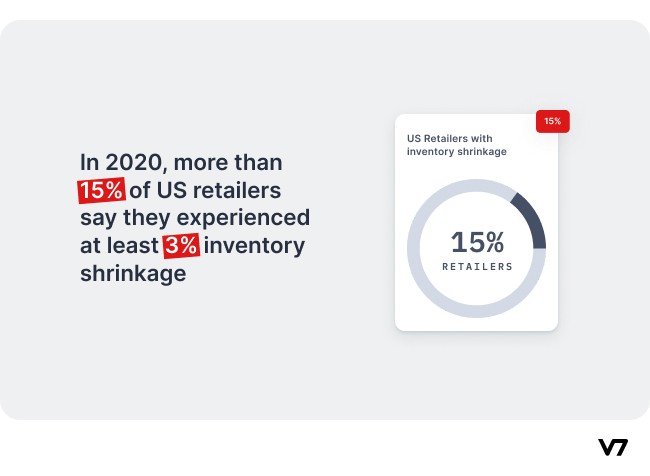

Product localization and identification help you find products that are hard to access, or which have fallen on the floor, got lost, or wedged between other items—and so on. This can help warehouse managers prevent inventory shrinkage more effectively.

In fact, inventory shrinkage is a major problem in the U.S. In 2020, more than 15% of US retailers say they experienced at least 3% inventory shrinkage.

This is often down to things like theft, mishandling, or human errors.

Now—

Implementing artificial intelligence in logistics for product localization and identification is relatively simple.

You can start by adding shelf-monitoring cameras that will rely on computer vision technology to alert your staff whenever empty shelves need restocking.

As well as adding cameras to your shelves, it’s beneficial to help your staff by incorporating a product recognition system into your apps. With this, a staff member can point their phone at a shelf and the items will be automatically counted. This saves time and improves accuracy.

Product localization and identification can benefit customers, too, by showing them in real-time on your website exactly what products are available and what products aren’t.

This means they can decide whether or not to place an order with you, and you can avoid potential material shortages.

Warehouse Automation and Management

This example of AI in logistics and supply chain continues what we’ve discussed above.

Warehouse management automation allows you to reduce (or eradicate altogether) labor-intensive tasks, such as data entry and picking, thereby reducing injury and fatigue while boosting productivity—and saving you money.

Indeed, according to a 2018 report from the U.S. Bureau of Labor Statistics, labor expenses set a warehouse back by as much as $3,700,000 each year. The fact that warehouse automation can save you money is doubly important at a time when supply chain issues are rising, which is leading to an upswing in operational costs.

Warehouse automation includes inventory management and data collection. And while investing in the initial AI technologies for the supply chain will cost you money, the long-term benefits far outweigh any short-term losses.

What’s more, while just 12% of businesses were using AI technology in their warehouses in 2020, this is expected to jump by 60% over the next six years.

What types of technology are we talking about in the context of transforming warehousing processes?

Let’s take a look at some essential AI use cases in logistics:

Goods-to-Person Systems

Goods-to-Person (GTP) is a type of automated storage and retrieval system (AS/RS) in which items are delivered to or retrieved from specific storage locations by automated vehicles called shuttles.

GTP is popular robotic process automation to cut out congestion while boosting efficiency. It includes vertical lift systems and conveyors that, when properly implemented, can more than double the speed of your warehouse picking.

Automated Guided Vehicles

Automated Guided Vehicles (AGVs) are a type of self-guided mechanized automation vehicle that rely on only a small amount of onboard computing power.

They use sensors (or sometimes wires or strips) to help them dash around the warehouse via a fixed path, transporting materials and delivering goods.

A human climbs abroad and “operates” the vehicle, but the vehicles are automated and move automatically using sensors that allow them to understand the warehouse inside-out.

They’re ideal for improving the accuracy of inventory processes and automating routine tasks as they move your staff and their cargo around the warehouse with speed.

However, employing AGVs makes most sense if you have a large warehouse environment with lots of space. If your warehouse is more cramped and there’s a lot of human traffic, AGVs are much less useful.

Voice Picking and Tasking

Pick-by-voice (also referred to as voice-directed warehouse procedures) combines mobile headsets with speech recognition software to determine the best pick paths on a warehouse floor.

Then, it relays all the necessary information to the warehouse worker (such as the quantity needed for an item), before guiding them along the right path so that they can either pick out a product or store one away.

The method negates the need for a handheld device (such as RF scanners), which frees up a picker to be more focused on the task at hand. It also improves efficiency and safety, as well as order accuracy.

Automated Sortation Systems

Sortation identifies systems on a conveyor, before using barcode scanners and sensors in conjunction with RFID to send them to a specific warehouse location.

Companies can implement an automated sortation system to improve their order fulfillment and eliminate the need for human supervision. Tasks like receiving, packing, and shipping can all be improved, with Amazon one of many big businesses that have already adopted robots to pick, sort, and transport goods in their warehouses.

There are two types of automated sortation systems:

Unit sorters

Case sorters

For both categories, there are multiple sortation systems that drop items onto a conveyor belt before diverting them to the right place in the warehouse.

AI-based systems make you less reliant on labor, improve order accuracy, and boost productivity and efficiency by working faster than your human workers.

Each of the above use cases relies on AI and machine learning in supply chain solutions. To learn more about the specifics, have a look at these articles:

Shipment Load Monitoring

The good news is that, while managing supply chains is racked with challenges, the worst of COVID-19 is over.

Things are improving—steadily.

The bad news, however, is that the shipping industry—and especially the ports—was dealt such a blow by the pandemic that it’s taking a long time to recover. And when the shipping industry is rocked, supply chains can grind to a halt.

Global trade is, however, recovering, with new container ships on the horizon to aid capacity.

Not just that, but AI-based solutions in the logistics industry are providing the perfect solution as the shipping industry looks to rebuild.

Container Loading Monitoring is a big focal point. It’s a service that deals with the supervision of merchandise being loaded into shipping containers. This typically takes place at the same factory where the merchandise was produced, before the container is sealed and sent to the port. From there, it’s exported.

It ensures importers always receive high-quality goods. Without it, they might suffer from poor loading procedures and receive defective goods.

How can AI technologies assist?

Artificial intelligence can give the importer complete assurance that they are getting exactly what they expected.

For example, AI systems can closely monitor the loading of cargo, looking out for items that may be prone to breakage, or which are extremely valuable.

Pre-shipment inspections can (and do) take place on the importer's side of things, but they rarely guarantee that the items loaded onto the containers are the inspected ones. The supplier, for example, might switch the items after an inspection has taken place.

If there’s a lack of trust between you and your supplier, implementing container loading monitoring can keep your suppliers in check.

Thanks to the use of AI in the logistics industry, you can quickly and accurately identify defects found during container load monitoring. Common defects that the software can find include:

Rejected carton boxes

Broken wooden pallets

Incorrect pallet stacking

Non-inspected lots

Using image processing and machine learning, AI software understands what goods are supposed to look like, before automatically alerting you when something isn’t right.

Defect Inspection and Quality Control

Consumers are more demanding than ever when it comes to the quality of the products they purchase. As such, a vital process for the logistics sector is defect inspection and quality control.

While this process is usually carried out by humans, the forensic nature of the task means that the process is a) tedious and b) can lead to human error, mostly as a result of mental fatigue born out of having to carry out repetitive tasks.

When human error creeps in, defects are missed—and consumers are left unhappy. This reflects badly on the business, it harms their reputation and it can cost them money. For example, this paper suggests that the price of fabrics drops by as much as 65% when there are defects.

AI in logistics is able to help with defect inspection and quality control. Not only does it speed up the process, but it also improves accuracy.

Using a combination of digital image processing, image classification, image segmentation, and computer vision, AI-based tools can spot defects that the human eye sometimes can’t catch the first time around.

The inspection process is as a result more efficient, while the amount of defective products that are sent to consumers is greatly reduced.

There are a number of problems here that AI in logistics can overcome:

Incomplete or Delayed Shipments

Cameras can look out for the presence or absence of shipping labels on packages. They can also send notifications if the labels are illegible.

When AI software is able to scan labels automatically during the loading process, the need for human labor is eliminated.

Damaged Items

Fujitsu is one company among many that have trained an AI model that uses object detection to spot damaged items on the assembly line.

The fact that Fujitsu is able to use an AI-trained model for this purpose means that the number of labor hours is significantly shortened.

Fujitsu’s model is so advanced that the Japanese company was able to circumvent the usual method of preparing training data using real images of defective products. Instead, they trained their model on images of items with simulated abnormalities. Despite this, their model is able to understand all the characteristics of the items it will be inspecting.

AI technology can also detect when a package has been dropped during shipping (and therefore potentially damaged).

Pro tip: Using computer vision software to spot damaged items is especially useful when shipping perishable goods.

Poor Packaging

Poor packaging can also contribute to damaged items. When your items are properly packaged, there’s less risk that they’ll become damaged during the supply chain operations.

Good packaging ensures your products are handled with care, particularly when loading and unloading. This results in improved customer experience and (among other things) fewer returns.

You can optimize your product packaging with AI systems. AI can help logistics companies design better packages for specific products, choose the appropriate materials, as well as the right size for each package, and it can alert you when a package has been tampered with before it’s shipped. This further ensures there are no delays during its journey, which effectively reduces the number of potential supply chain problems.

Long Wait Times

Lastly, if the above are taken care of by AI solutions, customer wait times will be shorter.

This will improve customer satisfaction, which can help you to build stronger relationships and ultimately—secure more sales.

Docks & Parking Lot Occupancy Detection

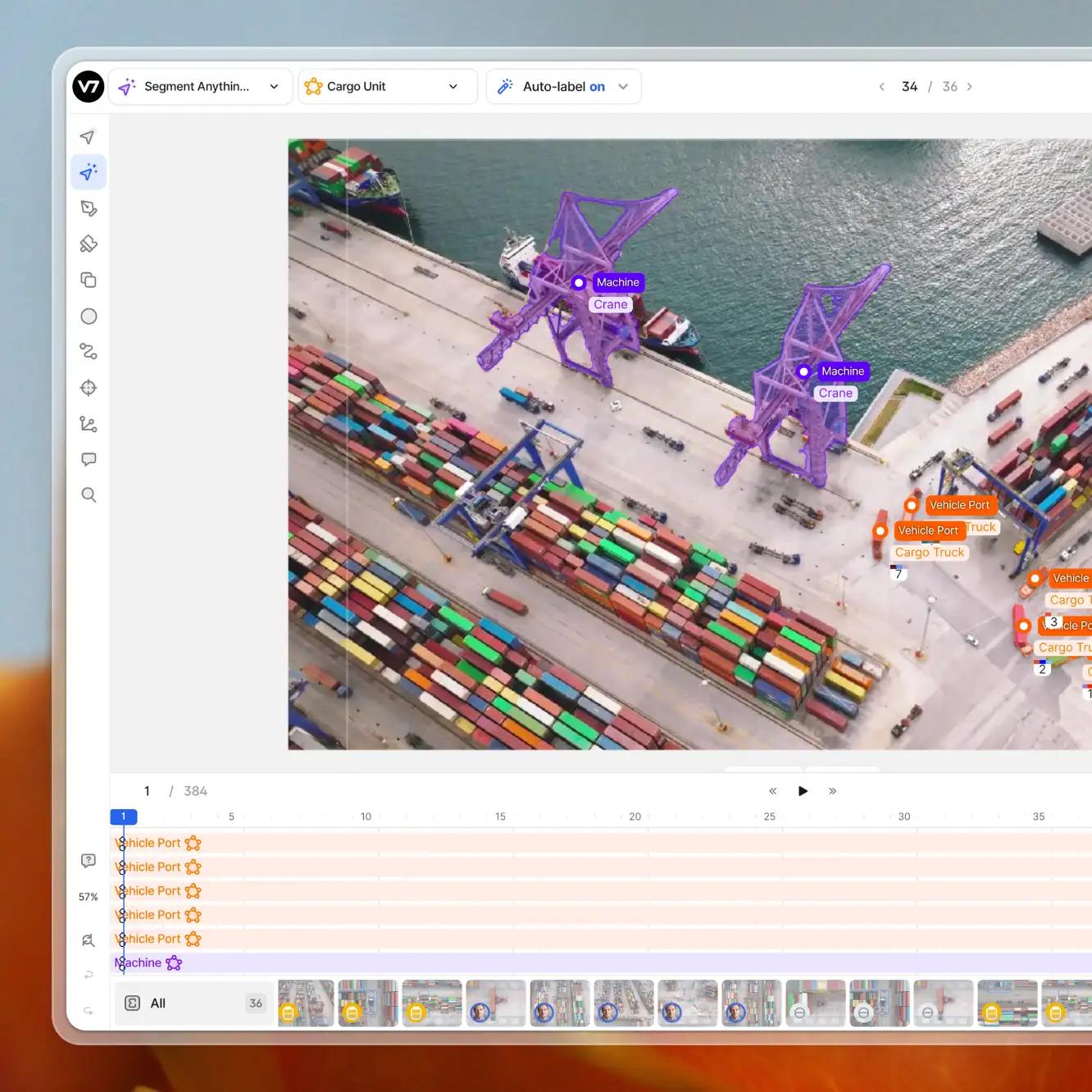

Computer vision technology is used to monitor docks and parking lots and can help to guide trucks to vacant parking spaces.

Neural networks, deep learning models, and surveillance cameras are used to spot whether a parking space is currently occupied by a vehicle or not. The CCTV cameras survey the parking lot, while deep learning models process the images.

Then, because computer vision systems provide accurate locations of the parking space, the software can guide truck drivers to a suitable parking space, thus improving efficiency.

Not just that, but the technology is able to detect trucks of all shapes and sizes.

And by closely checking whether or not a dock is fully occupied, and—if not—where there are available spaces, computer vision systems can support dock management as well.

This is all done based on real-time data, and the process can be performed in any type of weather condition.

More importantly, AI is able to optimize the use of parking spaces in ports (as well as other key logistics centers, such as an airport) by calculating how much space is available between two parked cars, and whether or not a particular vehicle will be able to fit.

While parking lot occupancy detection is also used by the transportation industry to reduce traffic congestion, it’s helpful in logistics because it improves shipping times by alerting staff when a truck has arrived, and directing the truck to an available parking space.

Not just that, but because you can leverage surveillance cameras that are already installed at the docks, no extra infrastructure is needed.

Intrusion and Theft Detection

AI in transport logistics can be helpful in many different areas—including keeping them safe.

It’s really important that you think about security measures that prevent intrusion and theft, thus saving you money.

AI plays a key role in intrusion and theft detection. The technology can monitor activity recorded by security cameras, keeping a lookout for anything suspicious and identifying objects of interest.

AI-driven intrusion detection systems identify objects based on their location, size, and movement. Using deep learning, they go further than standard intrusion detection systems, leveraging a more sophisticated algorithm to recognise various object types, while reducing the number of false positives.

All in all, they provide greater monitoring efficiency and improvement in warehousing operations.

Some practical applications:

Automatic License Plate Recognition

This is a smart infrastructure computer vision system that brings to your attention any vehicles that are on your premises—but which aren’t supposed to be there.

Automatic License Plate Recognition (ALPR) allows cameras to quickly read license number plates and it requires zero human interaction.

ALPR is used by the US homeland security to prevent crime and can be used in combination with object tracking and facial recognition to thwart criminal activity, as well as act as a deterrent.

Automatic license plate recognition is also currently used in electronic toll collection systems to toll vehicles that enter and exit roads.

Video Analytics

Video analytics lets you detect issues, and verify them before taking action.

Essentially, it gives you actionable data on the activity around your facility, thereby allowing you to quickly spot potential intruders.

Crucially, video analytics is able to identify the movements of vehicles and people at a scene while ignoring any type of motion that’s irrelevant. It can help with unusual motion detection and unusual activity detection.

Key areas of video analytics include access control systems that work in conjunction with intrusion detection sensors to get real-time alerts each time an unauthorized person tries to enter your facility.

This is extremely useful for cutting down intrusions and theft. It uses computer vision to detect faces, with facial data stored away in a database, and it’s one of the most widely used applications of AI in logistics.

Intrusion detection sensors, meanwhile, detect movement before triggering an alarm if an intruder has been identified.

Data is collected and annotated, neural networks are trained—and objects of interest are easily (and automatically) highlighted by deep learning algorithms. Typically, objects of interest are identified within seconds of a person entering a specific area.

The key for logistics companies is to choose areas to monitor. Multiple cameras will need to be used for intrusion detection sensors to be successful, too.

BOL Documents Processing

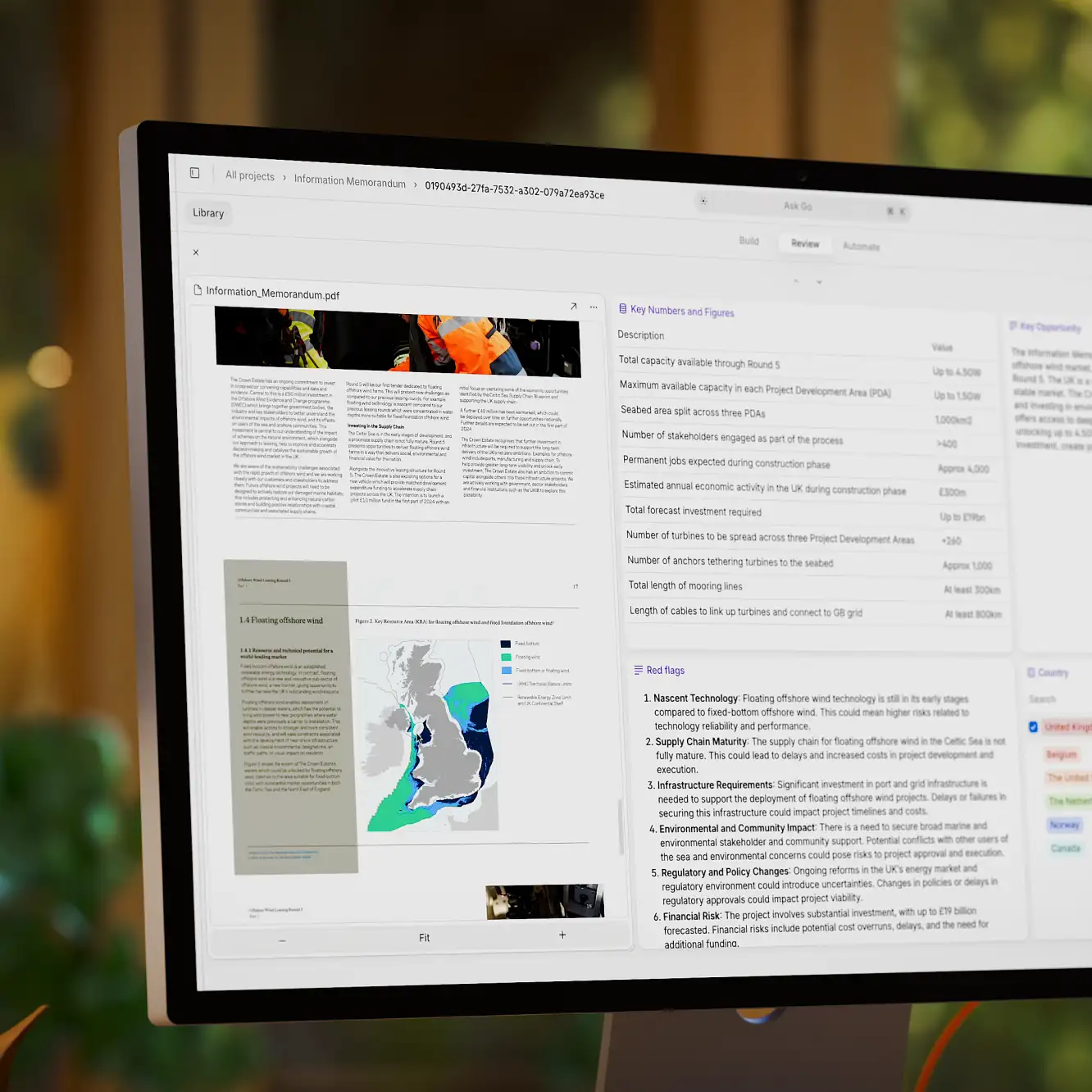

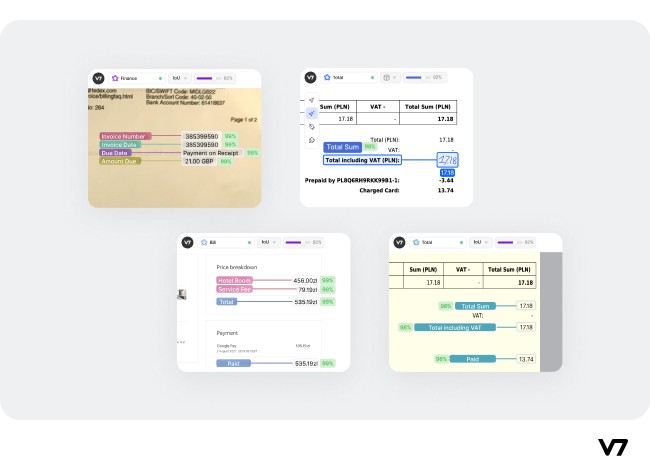

Document processing is when a document—such as a Bill of Lading—is translated into structured data that gives a company actionable insights.

Intelligent BOL document processing is when AI and technologies like computer vision and natural language processing translate documents that are not so easy to analyze manually.

There are many other shipping document workflows that can be automated with AI:

Air Waybills. Automatically extract shipment details for faster processing.

Freight Invoices. Simplify data extraction for accurate billing and payments.

Shipping Labels. Capture key information to streamline logistics operations.

First, the data is collected. Then, it’s pre-processed, classified, and extracted. The extraction phase is when machine learning models have obtained specific info, such as names, dates, and figures, before entering the post-processing and validation stage. It’s at this stage that duplicates and errors are highlighted.

Lastly, the extracted data is handed over to a business process.

Explore V7’s document processing solutions, and see what you can gain.

Bills of Lading have a few issues that need to be eliminated. These include:

Lost or Misplaced BOLs

When a BOL is lost or misplaced, delays can easily mount up in the shipping process. This means customers may receive their goods late.

Creating and issuing BOLs can be automated, with the benefit being that the chance of a BOL being lost or misplaced is reduced.

BOLs Not Properly Filled Out

If a company doesn’t correctly fill out a Bill of Lading, problems can arise at customs clearance. When this happens, more delays accrue—and there’s even a chance that the shipment will be rejected.

During the validation stage, machine learning models are armed with the extracted data. They then hone it, ironing out any errors and checking the accuracy of the information on BOLs. This prevents delays.

BOL Not Signed by the Relevant Parties

If this happens, the BOL might be invalidated—and the shipment will be turned away.

Companies can train AI to verify the signature on their BOLs. As a result, you can be sure that a shipment won’t be rejected because of invalid documents.

Key Takeaways

Using AI in supply chain and logistics is a no-brainer if you want to enhance your supply chain performance.

As we’ve seen, there are numerous ways you can use the technology. You can use computer vision in logistics to prevent inventory shrinkage, stop theft before it happens, improve your quality control processes and monitor your shipment load better.

All in all, risk management is improved, and—thanks to AI-driven predictions—logistics companies are getting better demand prediction insights. Essentially, with AI in logistics and supply chain management, you’ll reduce error rates, bring down operational costs and ensure you (and your customers) experience minimal stockouts.

Ready to get started? Contact V7 today to find out exactly how to add computer vision to your supply chain.